Enhancing Plasterboard Cart Safety: Insights from AWCI Webinar Panel Discussion

Plasterboard carts are essential tools in the construction industry, facilitating the transportation of heavy sheets and materials efficiently. However, improper use and a lack of safety precautions can lead to accidents and injuries on the job site. The Association of the Wall and Ceiling Industry (AWCI) USA organised a two-part webinar, sponsored and led by Magnum Tool Corp, where industry experts came together for a panel discussion on plasterboard cart safety. The webinar featured four presenters: Livia Lin, Edward Hanley, Jorge Vazquez, and Mike Hill. In this blog post, we will explore the 13 main discussion points from the webinar, offering valuable insights on safety regulations, appropriate utilisation, and training methods to prevent accidents.

1. Common Accidents

Several accidents can occur while using plasterboard carts, highlighting the importance of safety precautions. Accidents such as depression in concrete, boards sliding off carts and causing injuries, crushing of toes while pulling carts backward, and carts tipping over are common occurrences. By being aware of these risks, workers can take appropriate preventive measures to ensure their safety and the safety of others.

2. Caster Inspection

3. Cart Frame Inspection

Before using a plasterboard cart, it is essential to conduct a thorough inspection of the cart frame. Ensure that all components are free from fractures and cracks. Pay close attention to welded points, as cracked welds can compromise the cart’s structural integrity. Additionally, make sure the handles are securely welded and devoid of any damage. Using a broken cart can result in serious injuries, so it’s crucial to field destroy any unsafe plasterboard carts to prevent accidental use.

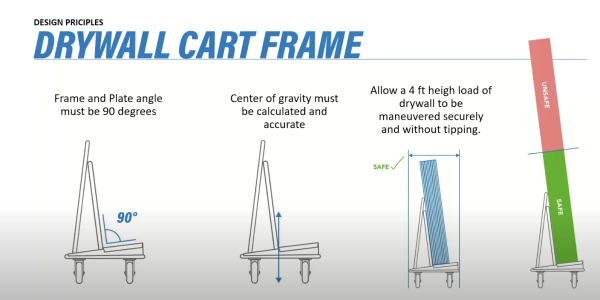

4. Design Principles of a Plasterboard Cart Frame

The design of a plasterboard cart frame plays a significant role in its stability and safety. The frame and plate angle should be maintained at 90 degrees to enhance stability during transportation. Additionally, accurately calculating and maintaining the center of gravity is crucial to prevent tipping while maneuvering loads of plasterboard. This design consideration enables secure transportation of up to a 4-foot (1.2-meter) height load of plasterboard without risking tipping accidents.

5. Controlling Access

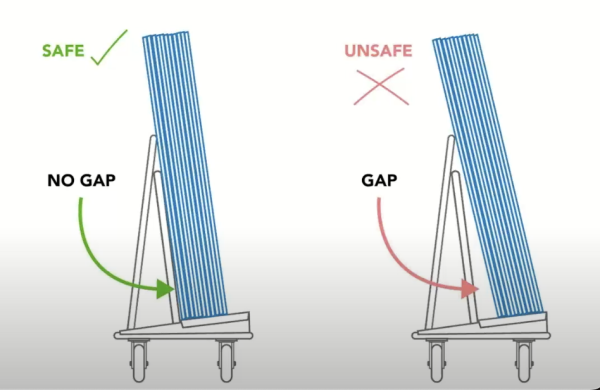

6. Correct Loading of Plasterboard

7.Locks vs Brakes

8. Operator Positioning

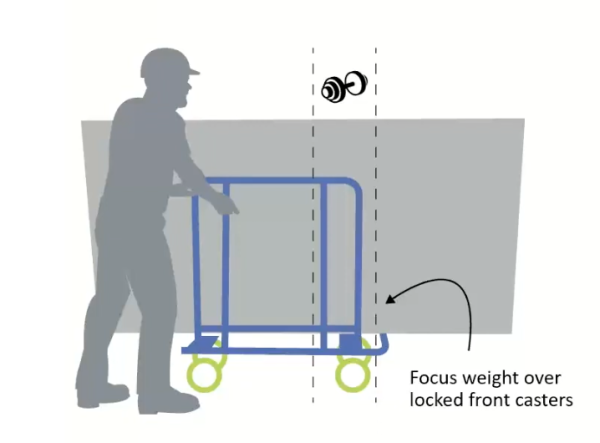

9. Balancing The Load

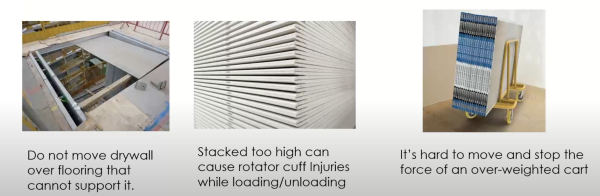

10. Do Not Overload

Take precautions when calculating load capacity. Even though a cart might be able to handle the weight, there are other considerations to keep in mind. These considerations include:

- Do not move plasterboard over flooring that cannot support it.

- Stacking the plasterboardl too high can cause rotator cuff injuries while loading/unloading.

- It’s hard to move and stop the force of an overloaded cart.

11. Other DO NOTS

- Do not shock load (drop heavy loads on the cart).

- Do not abuse plasterboard carts by allowing the wheels and caster to be slammed on the ground.

- Do not roughly plow through debris-filled floors, slam over obstacles, or traverse bumpy and rough surfaces.

- Do not leave carts outdoors and exposed to the elements.

- Do not ride on carts at great speed, run and push carts, or otherwise handle them recklessly.

- Do not attempt to catch or stop plasterboard from falling. Get out of the way. Let it go.

Adhering to these Do Nots will contribute to a safer work environment and help prevent accidents.

12.Workplace Pre-Planning and Communication

13. Training Musts

Training plays a vital role in plasterboard cart safety. It is essential to provide comprehensive training to all employees, even if specific provisions related to plasterboard carts are not explicitly outlined by OSHA. Hands-on training should cover loading and unloading techniques, inspection of carts for any damages, and adherence to safety policies in ramps and congested areas. Workers should be educated on proper hand placement to avoid crush injuries and be made aware of weight capacity. It is crucial to emphasize that the only safe action in the event of a falling cart is to get out of the way, as instinctively attempting to catch or stop the falling plasterboard can lead to severe injuries.

In conclusion, ensuring plasterboard cart safety is crucial for preventing accidents and injuries on job sites. By implementing the insights shared in the AWCI webinar panel discussion, including thorough inspections, controlling access to carts, practicing proper loading techniques, and providing comprehensive training, we can create a safer work environment. Additionally, being aware of the “Do Nots” when using plasterboard carts helps mitigate risks and promote safety consciousness.

To explore further information on plasterboard carts, we recommend checking out Wallboard’s range of plasterboard carts, the Wallboard Dolly Cart DC-1350 and The Telpro Troll Material Cart DC-1270 . These carts provide reliable and safe options for transporting gyprock on job sites.

For those interested in delving deeper into the topic and listening to the full panel discussion, we invite you to watch the two-part webinar on plasterboard cart safety:

By prioritising safety, adhering to best practices and staying informed about the latest guidelines, we can create a safer and more efficient work environment when using plasterboard carts. Remember, safety should always be the top priority.